Carbon to Currency • Six companies transforming CO2 emissions into high-value chemicals

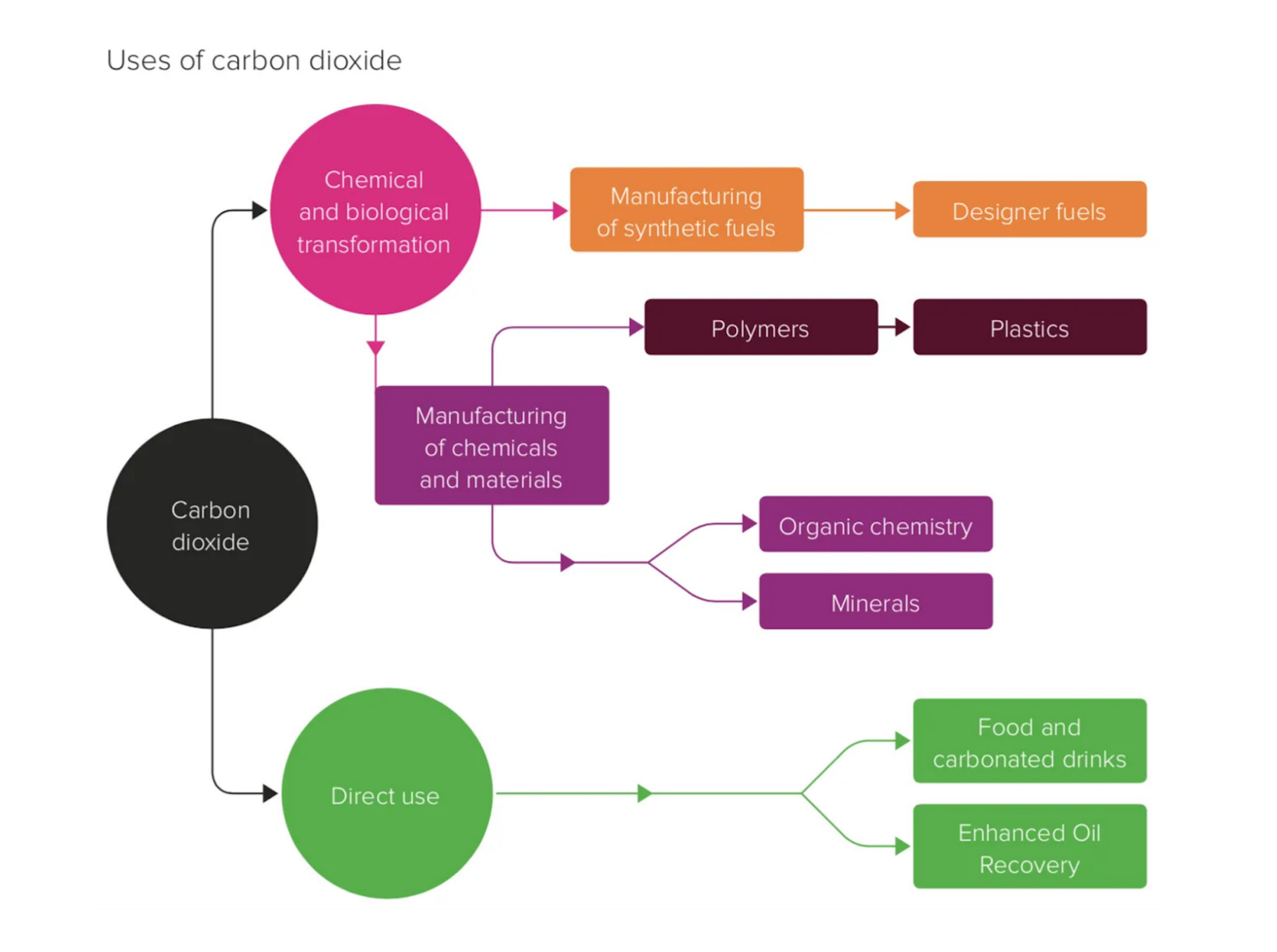

With the commercial landscape for carbon capture and reutilization largely limited to indoor agriculture and maintaining pressure in depleted oil wells, for now, carbon emissions generally remain a waste byproduct of energy consumption. Through the application of advanced electrochemical techniques however, a number of innovative companies are doing incredible work to repurpose CO2 emissions into high-value resources.

Combining novel catalysts and electrochemistry, companies operating at the pilot scale are beginning to demonstrate the viability for commercial CO2 conversion into a range of inputs including bio-plastics, synthetic fuels, building materials, and specialty chemicals. While the large-scale commercialization of these processes is likely many years away, companies leading the developments in this field represent a major step toward a future in which human activity is not only carbon neutral, but carbon negative.

Here we put together a short list of companies piloting CO2 conversion technologies that are worth keeping a close eye on in the coming years:

1) Econic Technologies

Based out of the UK, Econic Technologies is a company working to use catalyst chemistry to transform waste CO2 into short-chain polymers, a feedstock in the production of polyurethane. They note:

“Our catalyst technologies react CO2 with a group of chemicals called epoxides – traditional building blocks in the polymer industry – to make polymers that can contain up to 50% by weight of CO2.” - Econic

Leveraging this technology, Econic is able to substantially reduce the hydrocarbon inputs of plastic production while tailoring their chemistry to meet the specific requirements of the end product. Current applications include low molecular weight products like rigid and soft foams, sealants, and adhesives, however the company is working toward developing new products that demand higher molecular weights such as lubricants and surfactants.

2) Newlight Technologies

Using processes that take place throughout nature, Newlight Technologies is a California-based company developing conversion reactors that use enzymes and electroreduction to convert CO2 into PHB, a bio-derived polymer that can be used in the production of foodware plastics and synthetic leather. The material dubbed ‘Air Carbon’ can be melted and shaped like conventional plastic, however it remains biodegradable. Through their subsidiary, Restore Foodware, Newlight is now producing environmentally friendly disposable straws and utensils from the material.

3) Carbon Engineering

One of the most well established companies working to scale CO2 reduction is Carbon Engineering. Rather than taking carbon dioxide from concentrated industrial streams, the Canadian firm is developing large-scale systems to capture carbon dioxide directly out of the atmosphere and synthesize it into fuels for a range of different markets.

Here is how they outline the process:

While burning synthetic fuels consequently re-emits the captured carbon dioxide, implementing this system at scale can effectively create a neutral energy cycle while providing a medium for renewable energy to be stored outside grid-linked batteries (provided the conversion is powered using carbon-free energy).

While it has been suggested that continuing to burn hydrocarbons pulled out of the ground and offsetting their emissions by planting more trees is simpler and less expensive, continuing to advancince the development and implementation of direct air capture can theoretically reverse emissions over the long term once implemented at scale.

4) Sunfire

Also working to scale the production of synthetic fuels using CO2 is the German company Sunfire, which has developed a novel PTL (power-to-liquid) technology using high-temperature solid-oxide steam electrolysis, CO2 conversion via reverse water-gas shift reaction, and Fischer-Tropsch synthesis.

While the systems Sunfire has developed remain in their pilot phases, the company is working on solutions for a range of applications in the energy and chemical industries, architecting their systems in a modular fashion such that high efficiency and commercial scaling can be more easily achieved.

5) Avantium

Avantium is a Dutch company developing commercial-scale systems to derive high-value chemicals from carbon dioxide and bio-materials through the use of advanced catalysis and renewable-powered electroreduction processes. The company’s primary focus aims to resolve the environmental challenges of the plastics industry with PEF, a biodegradable plastic material derived from sugar that can be used to produce packaging, fabrics, and films.

Beyond biodegradable plastics however, Avantium is involved in the sustainable production of Glyoxylic and Glycolic Acid, speciality chemicals necessary in the production of polyesters and certain cosmetic products that are conventionally produced using fossil fuel based inputs. Using Avantium’s Volta technology, these chemicals can be sustainably produced using waste CO2 as a feedstock.

6) Liquid Wind

To circumvent the associated cost issues of direct air capture systems, some companies have been working to develop systems that capture carbon from sources where it is most concentrated. Liquid Wind is a Swedish company producing CO2 scrubbers for marine fleets that capture emissions and convert them directly into carbon neutral methanol. The synthetic fuel can then be used in a range of chemical products or blended with conventional gasoline to reduce the environmental footprint of internal combustion engines. By capturing carbon emissions from concentrated sources, Liquid Wind is able to build systems that are both environmentally friendly and economically viable without the need for heavy subsidization.

The goal is to eventually implement these synthetic fuels within a circular framework that will allow marine shipping (one of the world’s most emissions heavy industries) to be powered by a closed carbon loop.

Challenges yet to overcome:

At this point, the primary challenge to be overcome for CO2 reduction remains energy efficiency. While chemistry has made transforming carbon dioxide possible, the processes involved still require a substantial amount of reliable, cheap, and carbon-free energy to make them both economically and environmentally feasible. Barring any new scientific breakthroughs that may dramatically increase the energy efficiency of CO2 conversion, without creating an abundant supply of clean energy, the future for commercial CO2 reduction will likely remain limited to pilot-scale projects.

That being noted, while it will likely be some years before these technologies reach wide-scale implementation, the vision for commercial scale CO2 conversion remains promising. The companies involved are continuing to demonstrate that with enough clean energy is available there is immense potential for not only a carbon-neutral but carbon-negative future.

At Sphere, we’re working to develop the best tools to accelerate innovation in the green economy. If you’re a scientist working to develop high efficiency CO2 reduction processes, we’d love to see how we can support your research.

For more information about our solutions, visit: Sphere Energy - Flow Systems